Cooper Rotor

Cooper Rotor Copper Stator

Copper Stator Leakage Protector

Leakage Protector 20CrMo Carbonitrided Gear

20CrMo Carbonitrided Gear Main Handle

Main Handle Embedded Switch

Embedded Switch International Standard Thread: 1-1/4''

International Standard Thread: 1-1/4'' Stable Base

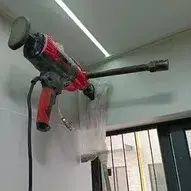

Stable BaseAlso known as a permanent lifting magnet, the diamond core drill is a highly practical power tool widely used in construction, renovation, and home improvement for drilling reinforced concrete. It is commonly used for projects such as underground protective barriers, load-bearing walls, floors, roads, dams, tunnels, and bridges. Additionally, it is essential for drilling cement surfaces for installations including electrical wiring, telephone lines, air conditioning units, gas pipes, drainage systems, fire protection systems, and plumbing fixtures.

Ground Coring

Ground Coring Brick Wall Coring

Brick Wall Coring Concrete Wall Coring

Concrete Wall Coring Wall Core Cutting for Air Conditioner Installation

Wall Core Cutting for Air Conditioner Installation Ground Core Cutting for Highway Guardrail Installation

Ground Core Cutting for Highway Guardrail Installation

Diamond Core Drill

Diamond Core Drill Wrench

Wrench Carbon Brush Set

Carbon Brush Set Water Hose

Water Hose User Manual

User Manual Carton Box

Carton Box Various Sizes of Core Drill Bits

Various Sizes of Core Drill Bits| Diamond Core Drill Bits | |||

| Diameter (mm) | Size of Segment | Total Length | Number of Teeth |

| (Length×Thickness×Height) | (pcs) | ||

| 32 | 15×3.8×10 | 450mm | 4 |

| 38 | 15×3.8×10 | 450mm | 5 |

| 52 | 24×3.8×10 | 450mm | 5 |

| 65 | 24×3.8×10 | 450mm | 6 |

| 78 | 24×3.8×10 | 450mm | 7 |

| 85 | 24×3.8×10 | 450mm | 8 |

| 92 | 24×3.8×10 | 450mm | 8 |

| 107 | 24×4.0×10 | 450mm | 9 |

| 117 | 24×4.0×10 | 450mm | 9 |

| 127 | 24×4.0×10 | 450mm | 11 |

| 135 | 24×4.0×10 | 450mm | 11 |

| 145 | 24×4.0×10 | 450mm | 11 |

| 152 | 24×4.2×10 | 450mm | 12 |

| 162 | 24×4.2×10 | 450mm | 13 |

| 172 | 24×4.2×10 | 450mm | 13 |

| 182 | 24×4.2×10 | 450mm | 13 |

| 192 | 24×4.5×10 | 450mm | 16 |

| 200 | 24×4.5×10 | 450mm | 16 |

| 212 | 24×4.5×10 | 450mm | 18 |

| 221 | 24×4.5×10 | 450mm | 18 |

| 252 | 24×5.0×10 | 450mm | 20 |

| 300 | 24×5.0×10 | 450mm | 26 |

| 350 | 24×5.5×10 | 450mm | 28 |

A diamond core drill is a drilling tool designed to extract cylindrical core samples from concrete structures.

Diamond core drills can cut through stone, concrete, slate, rock, brick, asphalt, and masonry.

The maximum drilling depth depends on the machine design and drill bit length. Most models can drill between 100mm to 300mm in depth.

Selection should be based on the strength and thickness of the concrete, rebar distribution, and the required core diameter and depth. Choosing the right power, torque, and drilling capacity is crucial for optimal performance.

Avoid drilling into high-stress areas, weak structural sections, joints, or edges where stress distribution is complex. Ideally, core samples should be taken from the central portion of the structure. Use a rebar locator to avoid embedded steel, fixtures, and pipelines, and select areas that accurately represent concrete strength and quality.

After each use, remove all dust and debris from the drill bit and machine. Check for loose components and tighten them if necessary. Regular lubrication of moving parts is recommended. Store the drill in a dry, clean environment to prevent rust and damage.