The manual type requires the operator to manually control the switch to activate or deactivate the magnetic force. It has a simple structure and lower cost, making it suitable for applications where lifting efficiency is not a primary concern or where flexible magnetic force adjustment is needed.

The magnetic force can be adjusted by changing the switch position, allowing for intuitive operation. However, it requires the operator to have experience and skill for proper handling.

In terms of safety, manual magnetic lifters require the operator to closely monitor the lifting process and respond to any changes promptly. To ensure safety, it is essential to strictly follow operational guidelines and take necessary precautions to protect both personnel and equipment.

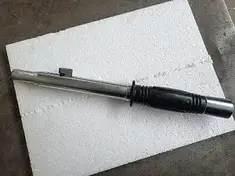

Designed with alloy steel galvanized lifting ring, ensures safety, stability, and rust resistance for long-term durability.

Rubber-coated anti-slip handle improves grip and operational safety.

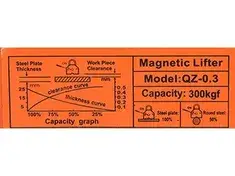

Side reference chart clearly indicates the relationship between plate thickness and lifting capacity.

Reinforced and thickened rotating shaft, paired with a mechanical labor-saving switch for easier operation.

Metal Parts Lifting

Metal Parts Lifting Metal Block Lifting

Metal Block Lifting Magnetic Lifting of Round/Curved Surfaces

Magnetic Lifting of Round/Curved Surfaces

| Model: QZ-0.1 | ||||||

| Lifting Capacity | Safety Factor | Weight | Shape Size (mm) | |||

| L | B | H | R | |||

| 100kg (flat steel objects) 50kg (round steel objects) |

3.5x | 3kg | 100 | 82 | 80 | 155 |

| Model: QZ-0.3 | ||||||

| Lifting Capacity | Safety Factor | Weight | Shape Size (mm) | |||

| L | B | H | R | |||

| 300kg (flat steel objects) 150kg (round steel objects) |

3.5x | 12kg | 175 | 105 | 100 | 185 |

| Model: QZ-0.6 | ||||||

| Lifting Capacity | Safety Factor | Weight | Shape Size (mm) | |||

| L | B | H | R | |||

| 600kg (flat steel objects) 300kg (round steel objects) | 3.5x | 25kg | 225 | 140 | 125 | 235 |

| Model: QZ-1 | ||||||

| Lifting Capacity | Safety Factor | Weight | Shape Size (mm) | |||

| L | B | H | R | |||

| 1000kg (flat steel objects) 500kg (round steel objects) | 3.5x | 43kg | 280 | 160 | 155 | 265 |

| Model: QZ-2 | ||||||

| Lifting Capacity | Safety Factor | Weight | Shape Size (mm) | |||

| L | B | H | R | |||

| 2000kg (flat steel objects) 1000kg (round steel objects) | 3.0x | 85kg | 360 | 210 | 185 | 426 |

| Model: QZ-3 | ||||||

| Lifting Capacity | Safety Factor | Weight | Shape Size (mm) | |||

| L | B | H | R | |||

| 3000kg (flat steel objects) | 3.0x | 160kg | 435 | 286 | 245 | 520 |

| Model: QZ-5 | ||||||

| Lifting Capacity | Safety Factor | Weight | Shape Size (mm) | |||

| L | B | H | R | |||

| 5000kg (flat steel objects) | 3.0x | 320kg | 540 | 316 | 295 | 650 |

A permanent magnet lifter is a lifting device that uses permanent magnets to lift and transport heavy ferromagnetic materials such as steel plates, pipes, and other metal objects.

It is primarily used for lifting ferromagnetic materials, including steel, iron, and nickel-based alloys.

Some manual magnetic lifters allow for magnetic force adjustment. By rotating the control switch, operators can modify the magnetic strength to accommodate different weights and sizes of objects.

Manual magnetic lifters are best suited for regularly shaped metal objects. If the object has an irregular shape, the uneven magnetic distribution may affect lifting stability.

When selecting a magnetic lifter, consider lifting capacity, magnet type, safety features, size and design, durability, and structural strength to ensure safe, efficient, and reliable operation.